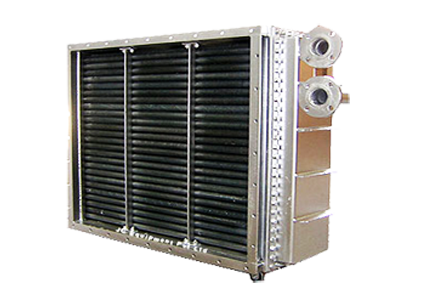

Finned Tube Heat Exchangers Manufacturer India

We at JC Equipments Pvt Ltd ASME Certified manufacturers of Finned heat exchangers in India offer the best Finned Tube Heat Exchanger for your applications using Europe Technology ie., with Spiral Wound Finned Tubes.

Why JC Finned Tube heat exchanger?

Spirally wound Fin material gives more efficiency, strength and suitalbe for high internal pressure. We offer variety of tube material and fin materials for your requirments.

JC Finned Tube Heat Exchanger Manufacturers India

FTH is a pressure vessel which cools a circulating fluid within finned tubes by forcing ambient air over the exterior of the tubes. It does not required water. Major Elements of Finnned Tube Heat Exchanger: Tubes, Fins and Fan (Actuating Device for Heat Transfer) Finned Tube Material: The material selection is made as per Process Application, And Cost of Heat Exchangers.

We use following materials for Constructions: Carbon Steel, Stainless Steel, Admiralty brass, Copper and Exotic Alloys, Seamless, and Welded Stainless Steels, Seamless, and Welded, 2205 Duplex, Copper Nickel, Admiralty Brass, Titanium.

Fin Materials: We use mostly Aluminum Fins and Copper Wire Fins for Specific Applications. Galvanized Iron Fins – For Low cost Projects.

- Stainless Steel Finned Tube Heat Exchangers

- Copper Finned Tube Heat Exchangers

- Finned Coil Heat Exchangers

- Brazed Fin Heat Exchanger

- Aluminium Finned Heat Exchanger

- ASME Section I & VIII Division 1

- TEMA

- API 660

- API 661

- National Board

- Inspection Agency: HSB Global Standards

- ASME Certificates U and S

- NB certification

- Radiography, Liquid Penetrant, Ultransonic, Hardness,

- Mag Particle (Wet and Dry), Surface Roughness,

- Tensile, Chemical and Physical Analysis

Applications: Finned Tube Heat Exchanger for Hydrocarbon process and steam condensers, Large engine radiators, Turbine lube oil coolers, Turbine intercoolers, Natural gas and vapor coolers, Combustion pre-heaters, Finned Tube Heat Exchanger for Flue gas re-heaters.