Thermal design Calculation

Q = UA ?Tlm After determination of the required heat transfer surface area, Other Mechanical Design are made, With reference to Process applications.

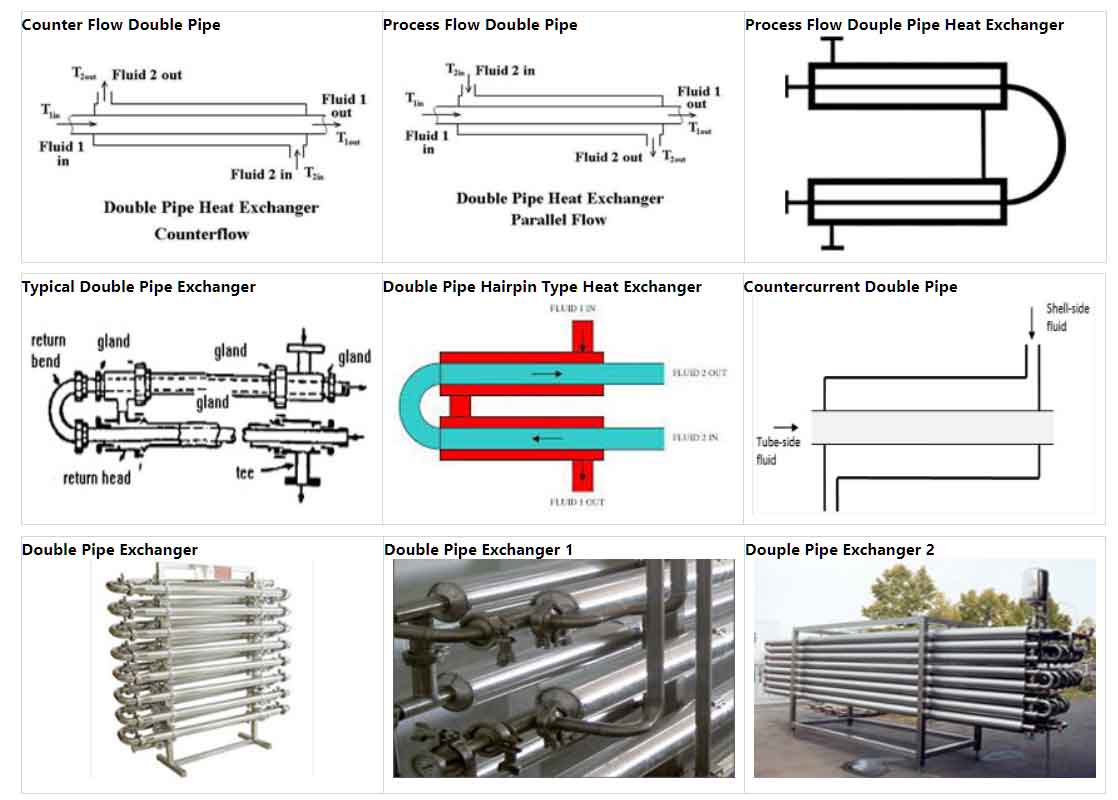

We JC Equipments Pvt Ltd Coimbatore India manufacturers of double pipe heat exchangers in India. A double pipe heat exchanger like Shell and Tube Heat Exchangers. We provide high and international quality standards double pipe heating system. We using latest raw material in the making development of double pipe heat exchangers.